500kg Autonomous Ground Vehicle

A half-ton armored tracked vehicle that navigates on its own. I designed the motors, built the autonomy stack, wrote the ground control station, and engineered the communication system.

Project Overview

As part of the TEKNOFEST Unmanned Ground Vehicle competition (Team Kaplan, ID: 647407), I worked as the lead engineer responsible for most of the vehicle's core systems. The Kaplan is a 500 kg tracked vehicle built on a 6061-T6 aluminum chassis with 316 stainless steel armor.

It was designed to operate fully autonomously in extreme conditions — climbing 45% grades, handling 20% side slopes, rolling over 20cm obstacles, and crossing water. My job was to design the powertrain, build the brain, and make sure it could talk to the operator reliably.

This wasn't a simulation or a concept — the vehicle was physically built, assembled, tested, and driven. The sections below explain what I did on each system.

My Responsibilities

- →Custom BLDC motor electromagnetic design

- →Full autonomous navigation stack

- →Ground control station (Next.js)

- →Dual-channel communication system

- →Computer vision & sign recognition

- →Webots simulation environment

Systems I Built

Each of these was designed, implemented, and tested by me as part of the team.

Electric Motor Design

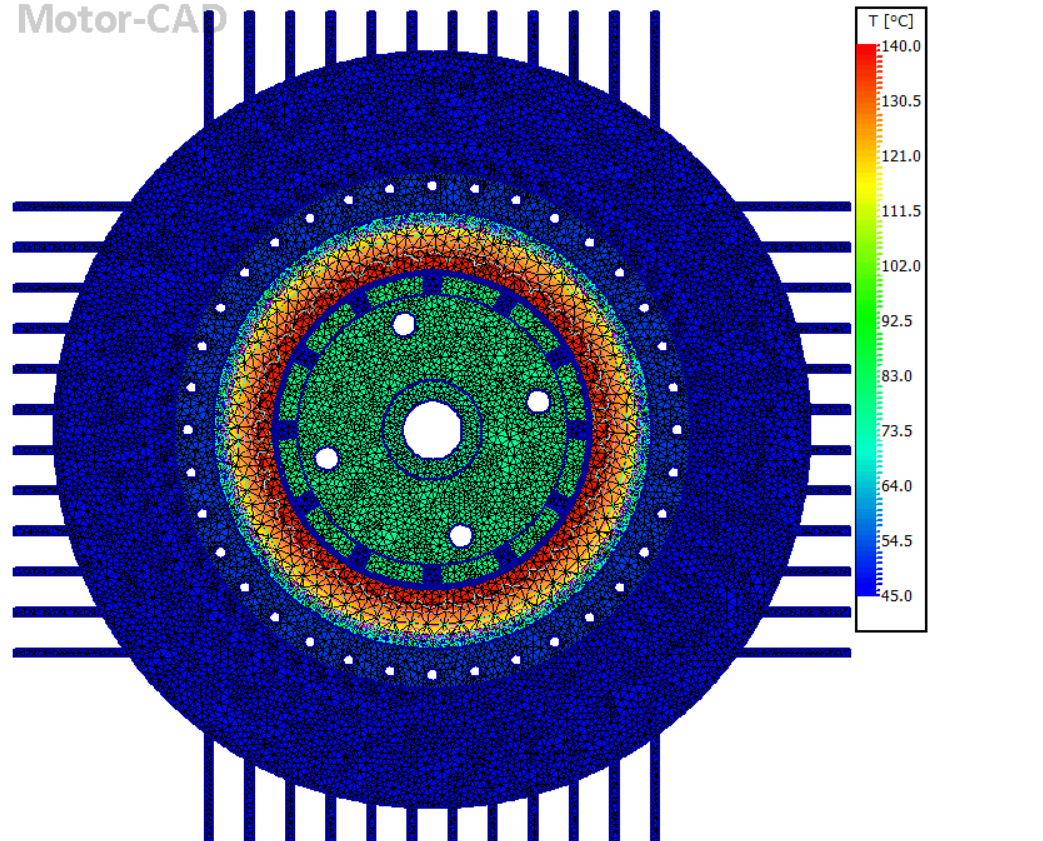

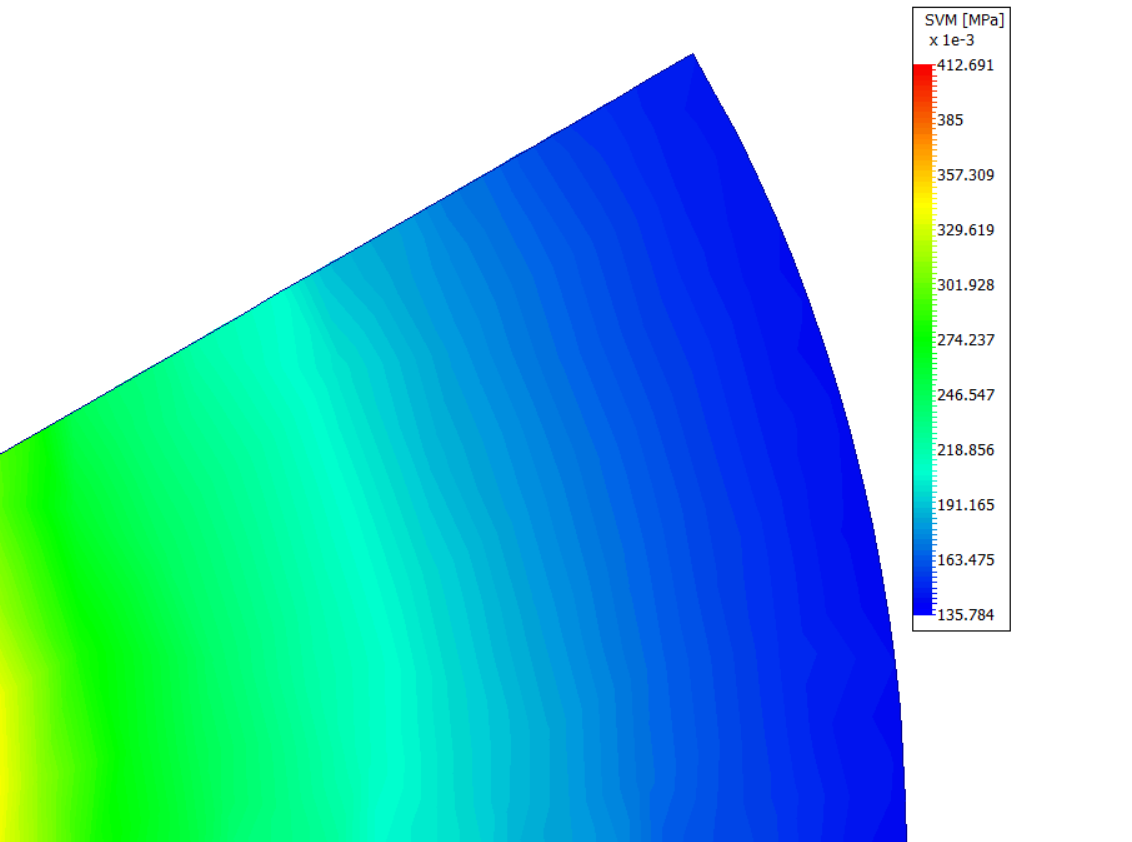

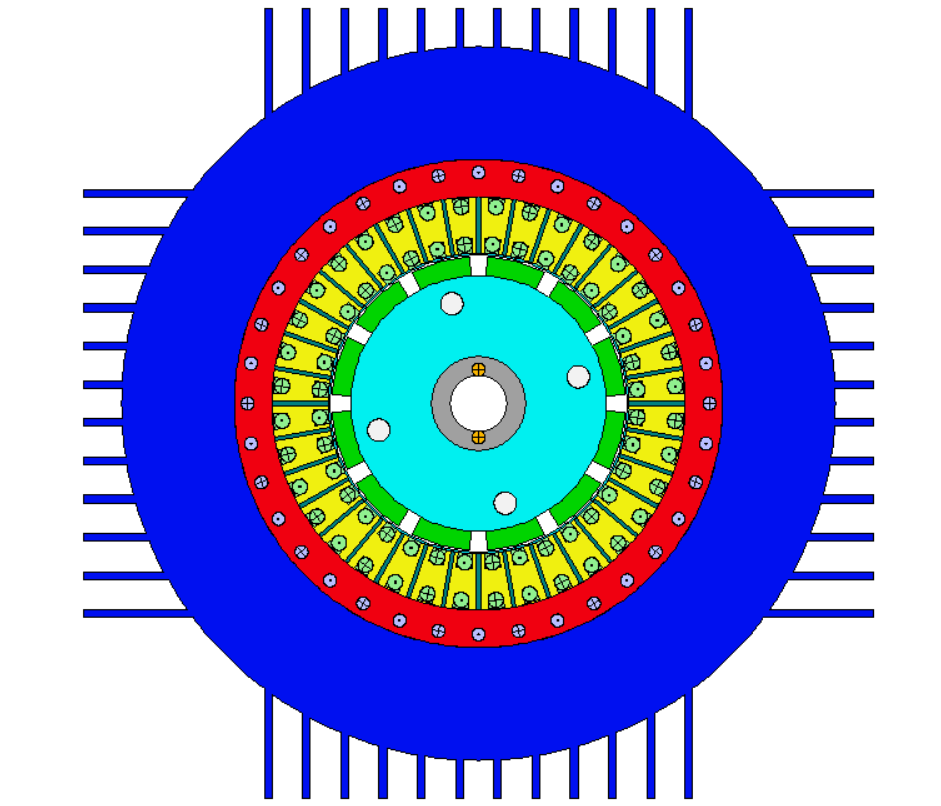

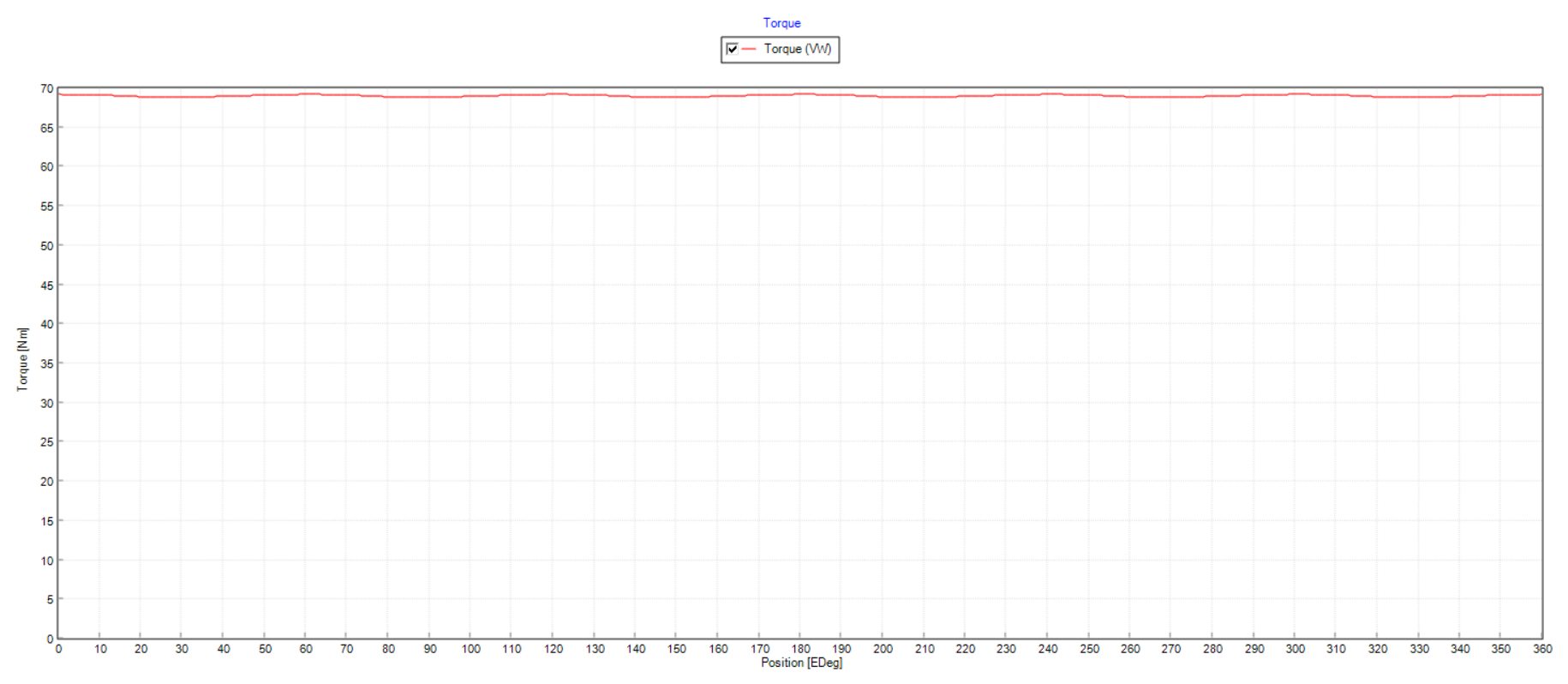

Designed a custom 48V, 8-pole Permanent Magnet BLDC motor from scratch. Used Ansys MotorCad for electromagnetic analysis and thermal simulation, then validated flux density and performance in the Ansys Maxwell FEA suite.

Autonomous Navigation

Built the full autonomy stack — Raspberry Pi 5 for computer vision and sign recognition, APM 2.8 controller for real-time IMU-based navigation. Tested everything in a Webots simulation before deploying to the real vehicle.

Ground Control Station

Developed the operator dashboard in Next.js — live video feed, GPS telemetry, vehicle status, and manual override controls. This is how the operator monitors and commands the vehicle during missions.

Dual-Channel Communication

Engineered a redundant comms system: TP-Link WiFi for high-bandwidth video streaming, SIM808 GSM/GPRS for long-range command and GPS telemetry. Automatic failover from WiFi → GSM ensures the link never drops.

Sensor Fusion

Combined camera-based computer vision with IMU data, GPS, and encoder feedback for robust localization. The system handles GPS-denied areas by dead-reckoning from wheel odometry and inertial measurements.

Armored Tracked Platform

The physical vehicle — 6061-T6 aluminum chassis with 316 stainless steel armor. Tracked drive system handles 45% slopes, 20cm obstacles, and water crossings. Not a concept — this thing was actually built and driven.

Motor Design & Simulation

The vehicle runs on 4 custom-designed 0.75 kW BLDC motors. I did the full electromagnetic design in Ansys MotorCad, then validated with FEA thermal and stress analysis.

Left: Thermal simulation under load. Right: FEA stress analysis of the motor housing.

Media Gallery

Want to know more?

This project covered motor design, autonomous navigation, real-time communication systems, computer vision, and full-stack web development — all in one vehicle. If you're building something similar or want to discuss the technical details, I'd love to chat.

Get in touch